Crush Resistance (SLA vs. Al)

Can a 3D printed structure outperform an aluminum tube in crush resistance?

Aluminum tubes have fairly remarkable stiffness and strength per weight – can we replicate that by customizing the geometry of a 3D printable design?

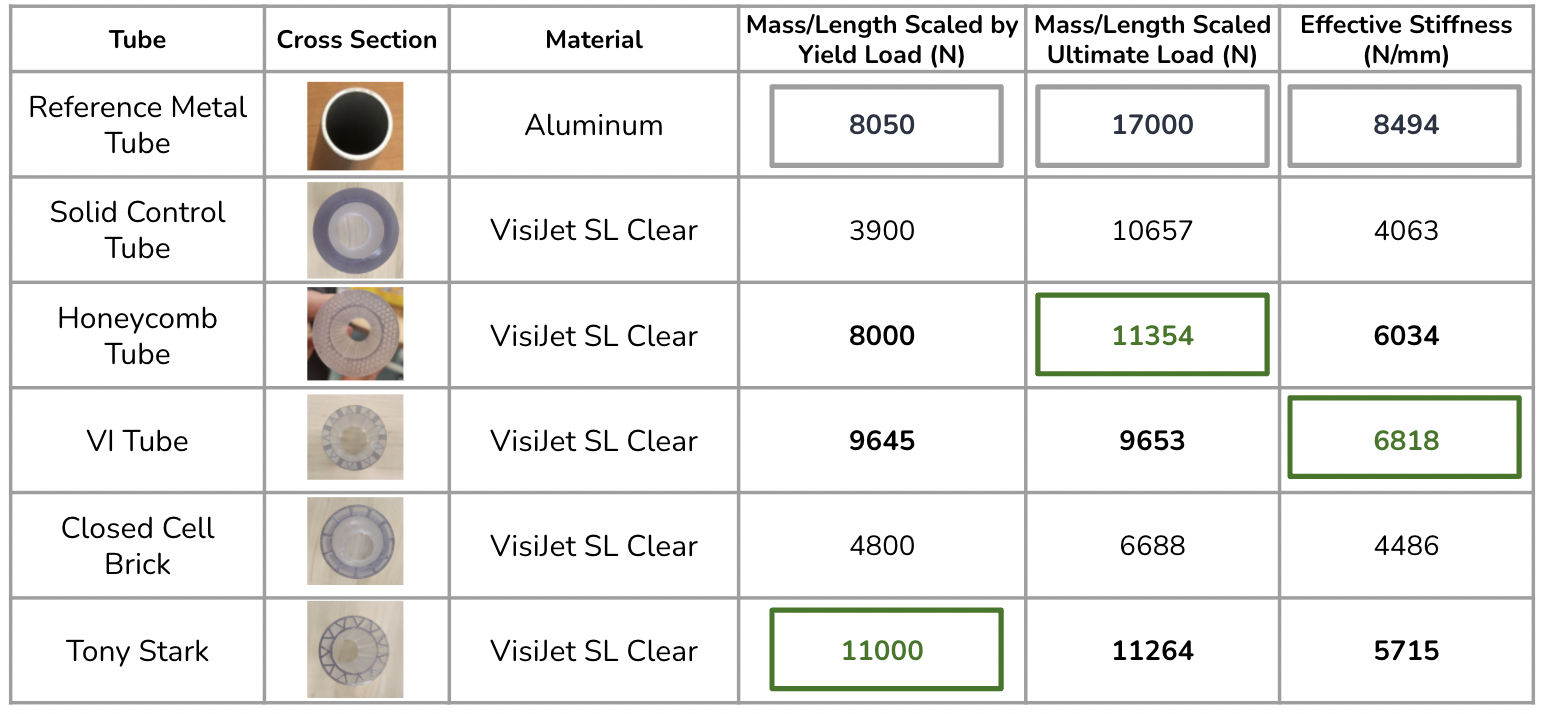

Worked on a team of 4 people to design and test various iterations of 3D printable tubes to create an outcome that would match or outperform T6-6061 Aluminum tubing

First team ever to achieve this brief

Step 1: Material Choice

Aluminum is good – but we set out to see if we could make something better.

We started by choosing a material and printing process. As a team we ended up landing on SLA printing for its superior uniformity and quality.

Step 2: Design Iteration & Testing

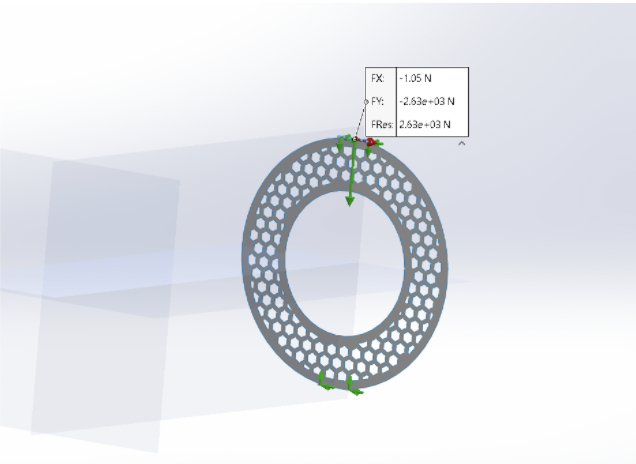

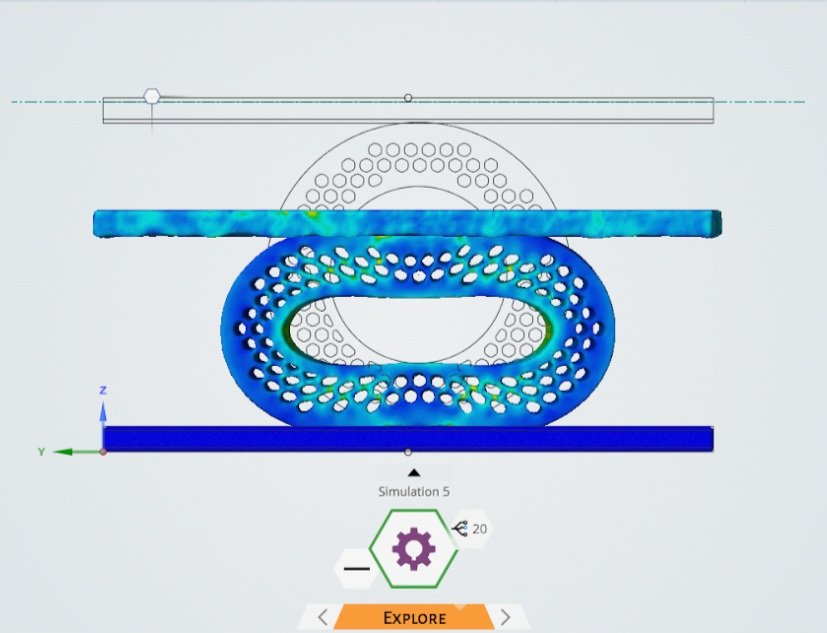

After deciding how we wanted to make our tubes, we moved onto testing various designs. This testing occurred via MTS machine loading and with modeling softwares: namely SolidWorks and Ansys Discovery.

Example of SolidWorks FEA on a slice of the Honeycomb design

Crush analysis on the Honeycomb tube in Ansys Discovery

Step 3: Analyze Data

Two tube designs were able to outperform the Aluminum control when scaled for mass and length.

We were also able to achieve a notably high ultimate load with our selected material – which our professor and we contributed to design advantages.